Enhancing Manufacturing Output with cnc turning service

In the world of precision engineering and industrial production, consistency and accuracy are paramount. Manufacturers are constantly seeking advanced solutions to improve efficiency, reduce waste, and produce components that meet exacting specifications. One such innovation at the heart of modern machining processes is the cnc turning service. With its ability to fabricate high-precision cylindrical parts at scale, this service has become a fundamental part of various industries, including automotive, aerospace, medical, and consumer electronics.

This article delves into the details of cnc turning service, its applications, benefits, and why it continues to be one of the most valuable services for companies aiming for operational excellence.

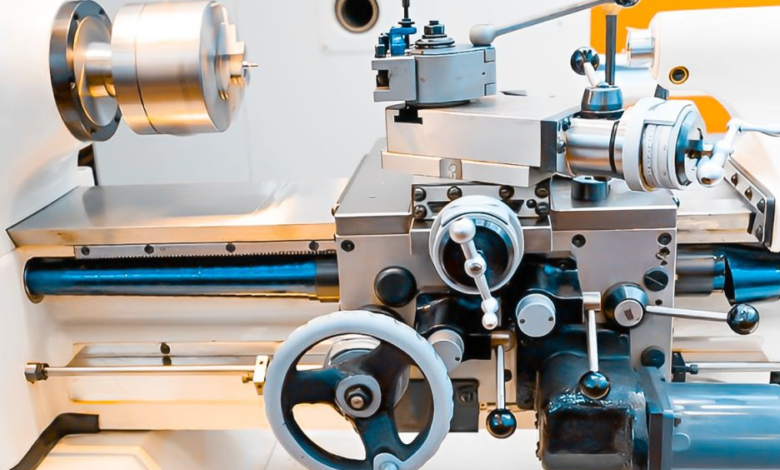

Understanding cnc turning service

cnc turning service involves a highly controlled machining process where a cutting tool removes material from a rotating workpiece to form the desired shape. This is executed using a CNC (Computer Numerical Control) lathe that follows digital instructions derived from a 3D CAD design. Because it’s computer-controlled, CNC turning offers exceptional accuracy, fast production times, and repeatability that manual processes simply cannot match.

The service is primarily used for creating symmetrical parts like rods, shafts, bushings, nozzles, and other components that require tight tolerances and consistent surface finishes.

Core Process of cnc turning

The cnc turning process starts with a digital design file which is converted into a language the machine understands—G-code. Here’s a step-by-step breakdown of how it works:

- Design & Programming: Engineers create a CAD file, which is then processed by CAM software to generate tool paths and machine commands.

- Material Setup: Raw material (usually in bar stock or billet form) is mounted into the machine’s chuck.

- Machining Operations: The material rotates at high speed while the cutting tool moves along multiple axes to shave, drill, bore, or thread the workpiece.

- Tool Changes: Automatic tool changers can switch between various tools, enabling multiple operations in one cycle.

- Finishing & Inspection: The completed part is deburred, cleaned, and inspected to ensure it meets the required specifications.

See also: Essential Technology for Small Business Owners

Benefits of cnc turning service

1. Precision Engineering

Modern CNC lathes can deliver tolerances within ±0.001 mm. This precision is essential for mission-critical parts used in aerospace, defense, and surgical equipment.

2. Consistent Quality

Once programmed, the CNC machine reproduces identical parts repeatedly, ensuring consistent quality in every batch—whether it’s 10 or 10,000 units.

3. Reduced Lead Time

Automation significantly cuts down the time required for each machining cycle. There’s minimal manual intervention, which speeds up production while reducing the risk of errors.

4. Versatile Material Handling

cnc turning service providers are equipped to work with a wide range of materials, including:

- Aluminum – Lightweight and corrosion-resistant

- Stainless steel – Durable and used in food, medical, and construction industries

- Brass – Highly machinable and ideal for plumbing and electronics

- Titanium – High strength-to-weight ratio, perfect for aerospace and implants

- Plastics – Engineering polymers like Delrin, Nylon, and PEEK

5. Cost-Efficiency

Although the initial setup may involve programming and tooling costs, these expenses are quickly offset in high-volume production runs due to the speed, accuracy, and low waste levels.

Industries That Rely on cnc turning service

The widespread adoption of cnc turning service is not limited to a single sector. Its ability to deliver reliable and precise components makes it indispensable in many areas:

- Aerospace: Engine housings, fasteners, and control components that must withstand extreme conditions.

- Automotive: Driveshafts, pistons, gearboxes, and custom parts for performance upgrades.

- Medical: Orthopedic implants, dental abutments, and surgical tool components.

- Electronics: Precision housings, pins, terminals, and mini connectors.

- Oil & Gas: Sealing components, couplings, and threaded connectors that require corrosion resistance and dimensional stability.

Each industry depends on the repeatability and material compatibility that cnc turning service offers.

Types of cnc turning machines

Different machines are used within CNC turning service each offering unique capabilities:

- 2-Axis CNC Lathes: Suitable for simpler operations involving basic cylindrical shapes.

- Multi-Axis Turning Centers: These machines offer up to 9 axes of motion, allowing for complex geometries and reduced setup times.

- Swiss-Type Lathes: Ideal for extremely small and intricate components, commonly used in watchmaking, medical devices, and microelectronics.

- Live Tooling Machines: Equipped with rotating tools to perform drilling or milling operations alongside turning in one setup.

Selecting the right machine depends on the part geometry, material, and production volume.

How to Choose a cnc turning service Provider

Selecting a competent provider ensures the quality and reliability of your finished products. Here’s what to look for:

- Technical Expertise: Choose a team with experience in your industry and a track record of producing complex parts.

- Advanced Equipment: Ensure the facility is equipped with multi-axis lathes, live tooling, and quality inspection tools like CMMs.

- Certifications: Look for providers certified under ISO 9001, AS9100, or medical-grade standards depending on your product requirements.

- Communication & Support: The ability to consult with engineers, receive design feedback, and get timely updates is critical.

- Post-Processing Capabilities: Services like heat treatment, anodizing, or surface finishing add value to your components.

Innovations in cnc turning service

As manufacturing enters the age of Industry 4.0, cnc turning service is also evolving:

- Smart Machining: Integration with IoT sensors and data analytics tools allows real-time monitoring of tool wear, part quality, and energy usage.

- Automation & Robotics: Robotic arms handle part loading and unloading, increasing productivity in lights-out manufacturing environments.

- Eco-Friendly Machining: Water-based coolants, chip recycling, and energy-efficient machines are being adopted for sustainability.

- Cloud-Based CNC Platforms: Cloud storage and remote programming are enabling quicker setup and better data management.

These advancements not only increase output but also ensure long-term competitiveness for machining service providers.

Conclusion

In today’s high-demand industrial environment, precision, speed, and reliability are key drivers of success. cnc turning service delivers all three, offering manufacturers a robust solution for producing intricate components with confidence. From prototyping to mass production, it enables companies to scale quickly while maintaining the highest quality standards.

As industries continue to innovate, CNC turning will remain a critical manufacturing process—evolving alongside technology and setting new benchmarks for what’s possible in precision machining.