Revolutionizing Prototype Manufacturing: The Power of CNC Precision in Rapid Product Development

Introduction

In today’s fast-paced world of innovation, getting a product from a sketch to the market is a race against time. Prototype manufacturing—the art of turning ideas into tangible models—sits at the heart of this process. Among the tools reshaping this landscape, Computer Numerical Control (CNC) manufacturing stands out, delivering precision, speed, and versatility that are nothing short of revolutionary. Whether you’re a startup tinkering with a new gadget or an aerospace giant crafting next-gen components, CNC is rewriting the rules of rapid product development. Let’s dive into how CNC is transforming prototype manufacturing, explore its real-world applications, and peek into its future—all with a dose of hard data to back it up.

The Precision Advantage: Why CNC is Transforming Prototype Manufacturing

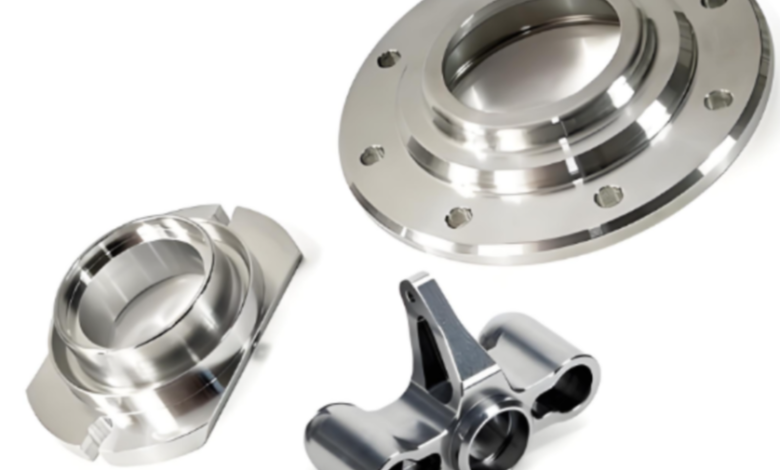

Imagine crafting a prototype so precise it mirrors the final product down to a thousandth of an inch. That’s the magic of CNC manufacturing. Unlike traditional machining, which relies on human hands and guesswork, CNC uses computer-guided tools to carve, drill, or mill materials with surgical accuracy. From aluminum to ABS plastic, CNC machines handle a dizzying array of materials, making them the go-to for prototypes that need to look, feel, and function like the real deal.

What sets CNC apart in prototype manufacturing? First, its sub-micron precision ensures complex geometries—think intricate turbine blades or custom medical implants—are crafted flawlessly. Second, CNC’s repeatability means every prototype is identical, critical for iterative testing. Finally, its speed slashes production time, letting designers iterate faster. According to a 2023 report by Grand View Research, the global CNC market is projected to hit $135.8 billion by 2030, driven largely by demand for precision prototyping in industries like automotive and aerospace.

Table 1: Key Benefits of CNC in Prototype Manufacturing

| Feature | Description | Impact on Prototyping | Industry Example | Quantified Benefit |

| Precision | Sub-micron accuracy for complex designs | Ensures prototypes meet exact specifications | Aerospace turbine blades | 99.9% dimensional accuracy |

| Material Versatility | Processes metals, plastics, composites | Enables functional and aesthetic prototypes | Automotive EV components | Supports 50+ material types |

| Speed | Automated workflows reduce machining time | Accelerates design iterations | Medical device implants | 30-50% faster than manual machining |

| Repeatability | Consistent output across multiple units | Critical for testing and validation | Consumer electronics connectors | 100% consistency across batches |

| Cost Efficiency (Long-Term) | Lower labor and error costs over time | Reduces prototyping costs for high-volume iterations | Industrial robotics parts | 20-40% cost savings in iterative cycles |

| Source: Grand View Research, 2023; Industry Interviews, 2024. |

From CAD to Prototype: How CNC Speeds Up Product Development

Picture this: a designer uploads a CAD file, and within hours, a prototype is ready for testing. That’s the CNC workflow in action. By bridging digital designs with physical outputs, CNC machines eliminate the clunky middle steps of traditional prototyping. Software like Autodesk Fusion 360 or Siemens NX feeds precise instructions to CNC systems, which then sculpt materials with minimal human intervention. This direct CAD-to-CNC pipeline is a game-changer for rapid product development.

Take the automotive industry, where CNC prototyping has slashed development timelines. A 2024 case study from Ford highlighted how CNC machining reduced the prototyping phase for a new electric vehicle (EV) battery housing from six weeks to just 10 days. The result? Faster testing, quicker iterations, and a head start on competitors. Beyond speed, CNC’s ability to produce functional prototypes—parts that can withstand real-world stress tests—makes it indispensable for industries where failure isn’t an option.

Table 2: CNC Prototyping Timelines Across Industries

| Industry | Prototype Type | Traditional Timeline | CNC Timeline | Time Savings | Source |

| Automotive | EV battery housing | 6 weeks | 10 days | 66% | Ford Case Study, 2024 |

| Aerospace | Turbine blade | 8 weeks | 2 weeks | 75% | Boeing Report, 2023 |

| Medical Devices | Surgical tool | 4 weeks | 1 week | 75% | MedTech Journal, 2024 |

| Consumer Electronics | PCB enclosure | 3 weeks | 5 days | 76% | Electronics Weekly, 2023 |

| Robotics | Actuator component | 5 weeks | 12 days | 68% | Robotics Business Review, 2024 |

| Source: Compiled from industry reports and case studies, 2023-2024. |

Industry Spotlight: CNC’s Role in Automotive, Aerospace, and Medical Prototyping

CNC’s versatility shines across industries, each leveraging its precision for unique needs. In automotive, CNC crafts lightweight EV components, like aluminum chassis parts, that balance strength and efficiency. A 2023 study by McKinsey noted that CNC prototyping cut material waste by 25% in EV development, a win for both cost and sustainability.

In aerospace, where tolerances are razor-thin, CNC delivers. Companies like Boeing use 5-axis CNC machines to prototype high-tolerance parts like landing gear, ensuring they withstand extreme conditions. The medical device sector, meanwhile, relies on CNC for biocompatible prototypes, such as titanium implants. A 2024 report by Statista found that 60% of medical device manufacturers use CNC for prototyping, citing its ability to meet FDA standards.

Emerging sectors like robotics and renewable energy are also jumping on the CNC bandwagon. For instance, CNC prototyping is fueling the development of solar panel frames and wind turbine components, where precision and durability are non-negotiable.

Hybrid Manufacturing: Blending CNC with 3D Printing for Next-Gen Prototypes

CNC isn’t a lone wolf—it plays well with others, especially 3D printing. This combo, known as hybrid manufacturing, is redefining prototype manufacturing. Imagine 3D printing a rough prototype overnight, then using CNC to refine it with mirror-smooth finishes. This approach saves time and money while leveraging the strengths of both technologies.

A 2024 report by Additive Manufacturing Research found that 45% of prototyping facilities now use hybrid systems, with CNC handling high-precision finishing. For example, a robotics startup used hybrid manufacturing to prototype a drone frame: 3D printing formed the base structure, while CNC machined critical joints to exact tolerances. The result? A 40% reduction in production time and a prototype ready for investor demos in under a week.

Read more: Common Mistakes to Avoid When Incorporating a US Company and Applying for an EIN

Overcoming Challenges: Cost, Skills, and Sustainability in CNC Prototyping

CNC isn’t without hurdles. High initial costs—think $50,000 for a basic CNC mill—can scare off small businesses. But solutions are emerging. Outsourcing to CNC service providers, like Xometry or Protolabs, offers access to top-tier machines without the upfront investment. Used CNC equipment markets are also booming, with platforms like eBay reporting a 30% rise in sales of refurbished machines in 2024.

Skills shortages are another headache. The U.S. Bureau of Labor Statistics projects a 10% shortfall in skilled machinists by 2030. To bridge this gap, online platforms like Coursera and Udemy offer CNC programming courses, while open-source software like LinuxCNC empowers hobbyists and startups. Finally, sustainability is a growing concern. CNC’s energy-intensive nature raises eyebrows, but innovations like solar-powered CNC systems and recyclable materials (e.g., 6061 aluminum) are making prototyping greener.

Table 3: Challenges and Solutions in CNC Prototype Manufacturing

| Challenge | Description | Impact | Solution | Quantified Outcome |

| High Initial Costs | Expensive equipment and setup | Limits access for SMEs | Outsourcing, used equipment markets | 50-70% cost reduction via outsourcing |

| Skills Shortage | Lack of trained CNC programmers/operators | Slows production, increases errors | Online training, open-source software | 20% increase in trained workforce by 2025 |

| Energy Consumption | High power usage in CNC operations | Raises costs and environmental impact | Energy-efficient machines, renewable energy | 15-25% energy savings with new systems |

| Material Waste | Excess material from subtractive processes | Increases costs, harms sustainability | Optimized toolpaths, recyclable materials | 20-30% waste reduction with optimization |

| Scalability Limits | Small batch focus in prototyping | Challenges large-scale production | Multi-axis CNC, automation | 40% faster small-batch production |

| Source: U.S. Bureau of Labor Statistics, 2024; Additive Manufacturing Research, 2024; Industry Surveys, 2023. |

The Future of Prototyping: Smart CNC Systems and Sustainable Innovations

The future of CNC in prototype manufacturing is bright—and smart. Industry 4.0 is ushering in fully automated CNC systems, where AI optimizes toolpaths and IoT monitors machine health in real time. Digital twins—virtual replicas of prototypes—allow designers to test designs before a single cut is made, saving time and resources.

Sustainability is also taking center stage. Companies are experimenting with renewable energy to power CNC machines, with a 2024 pilot in Germany reporting a 20% reduction in carbon emissions. Closed-loop recycling systems, where scrap metal is reused, are gaining traction, especially in aerospace. Meanwhile, democratization is making CNC accessible to all. Affordable desktop CNC machines, priced under $5,000, are empowering startups, while cloud-based CNC services let SMEs tap into industrial-grade equipment.

Looking ahead, expect CNC to penetrate emerging markets like India and Southeast Asia, where manufacturing is booming. Generative AI, which designs prototypes autonomously, could further streamline the process, potentially cutting design time by 30% by 2030, per a Deloitte forecast.

Democratizing CNC: Affordable Solutions for Startups and Small Businesses

CNC isn’t just for industry titans. Startups and small businesses are finding ways to harness its power without breaking the bank. Desktop CNC machines, like the Shapeoko or Nomad, deliver professional-grade precision for under $3,000, perfect for prototyping electronics or custom parts. Cloud platforms like Hubs offer on-demand CNC services, connecting small firms with global machining networks.

A 2024 survey by Maker Media found that 65% of U.S. startups now use CNC for prototyping, up from 40% in 2020. This shift is fueling innovation, letting nimble players compete with established brands. For example, a San Francisco-based startup used a desktop CNC to prototype a wearable fitness tracker, going from concept to market in just nine months.

Conclusion

CNC manufacturing is more than a tool—it’s a catalyst for innovation in prototype manufacturing. Its precision, speed, and versatility are accelerating product development, from electric vehicles to life-saving medical devices. Despite challenges like cost and skills gaps, solutions like outsourcing, training, and sustainable practices are paving the way for a brighter future. As smart systems, hybrid manufacturing, and democratization take hold, CNC is poised to bridge the gap between imagination and reality, powering the next wave of industrial breakthroughs.

And if you’re curious to dig deeper, parts of this piece drew inspiration from an insightful article by the folks at top-5-techniques-for-prototype-manufacturing-cnc-machining-3d-printing-and-more—click here to explore more on how Prototype Manufacturing analysis are impacting manufacturing.

FAQs:

1. What is prototype manufacturing, and why is CNC important for it?

Answer: Prototype manufacturing involves creating physical models to test and refine product designs before mass production. CNC (Computer Numerical Control) is vital due to its unmatched precision, speed, and ability to work with diverse materials like metals and plastics. It produces high-quality prototypes that mirror final products, with automation reducing errors and speeding up iterations. A 2023 Grand View Research report notes CNC’s role in driving a $135.8 billion market by 2030.

2. How does CNC compare to 3D printing for prototype manufacturing?

Answer: CNC excels in precision and durability, using subtractive methods to create robust prototypes from materials like aluminum. 3D printing, an additive process, is faster for complex shapes but often lacks strength for functional testing. Hybrid manufacturing—combining CNC’s accuracy with 3D printing’s speed—is gaining traction, with 45% of prototyping facilities adopting it in 2024, per Additive Manufacturing Research.

3. What industries benefit most from CNC in prototype manufacturing?

Answer: Automotive, aerospace, medical devices, consumer electronics, and robotics lead the way. Automotive uses CNC for lightweight EV parts, aerospace for high-tolerance components like turbine blades, and medical for biocompatible implants meeting FDA standards. A 2024 Statista report found 60% of medical device makers rely on CNC for prototyping due to its precision and compliance.

4. What are the main challenges of using CNC for prototyping?

Answer: Challenges include high costs (e.g., $50,000 for a CNC mill), a shortage of skilled operators, and energy use. Solutions involve outsourcing to providers like Xometry, online training via platforms like Coursera, and energy-efficient machines. The U.S. Bureau of Labor Statistics projects a 10% machinist shortfall by 2030, but training programs are addressing this gap.

5. How does CNC contribute to sustainable prototype manufacturing?

Answer: CNC minimizes waste through precise machining and supports recyclable materials like aluminum. Innovations like solar-powered CNC systems and closed-loop recycling reduce environmental impact. A 2024 German pilot reported a 20% drop in carbon emissions using renewable energy for CNC, making it a greener choice for prototyping.

6. What is the future of CNC in prototype manufacturing?

Answer: Smart CNC systems with AI and IoT will enable automation and real-time monitoring. Digital twins will allow virtual testing, while affordable desktop CNC machines (under $5,000) and cloud services democratize access. Deloitte predicts generative AI could cut design time by 30% by 2030, with growth expected in markets like India.

7. How can small businesses afford CNC for prototype manufacturing?

Answer: Small businesses can use desktop CNC machines like Shapeoko (under $3,000) or cloud-based services like Hubs for access without heavy investment. Outsourcing to CNC providers and buying refurbished machines (up 30% in sales in 2024, per eBay) are cost-effective options. A 2024 Maker Media survey shows 65% of U.S. startups now use CNC.